Verzending 24–48 u • Levering in de hele EU • Veilige chemieverpakking

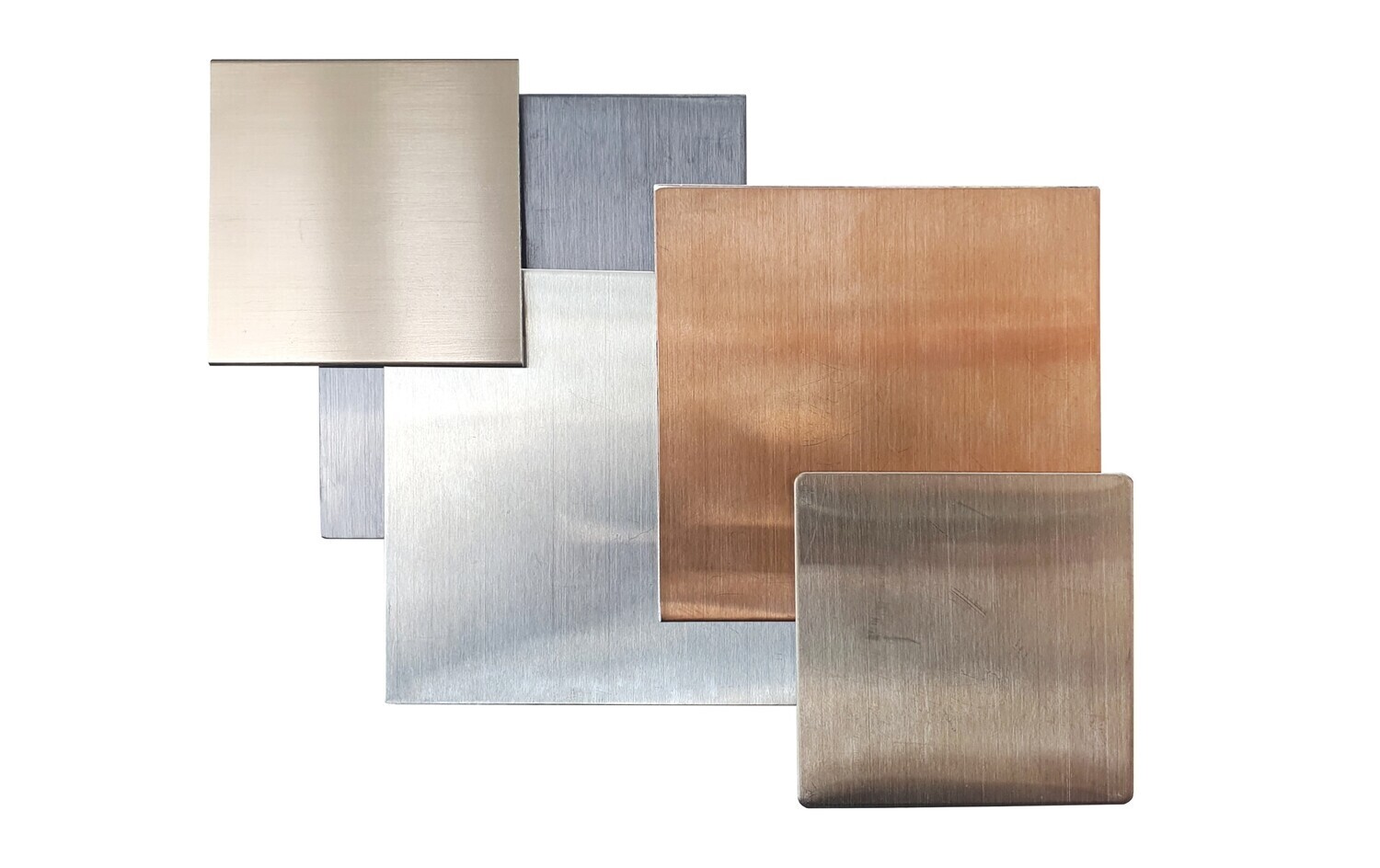

Graphite plate 2 x 250 x 500 mm 1 pc

SKU 904196

€ 206,41

In stock

1

Save this product for later

Graphite plate 2 x 250 x 500 mm 1 pc

Product Details

CAS number: 7782-42-5

Chemical formulas: 0.5-1% ash

Cation: C

Packaging: 1 pc

EAN: 8721028217516

Brand: Laboratoriumdiscounter

2 x 250 x 500 mm

Graphite plate is a versatile and high-performance material used in various industries for its exceptional thermal conductivity, electrical conductivity, and chemical resistance properties. It is commonly used in applications such as heat exchangers, electrodes, and lubricants. With its unique combination of properties, graphite plate offers excellent performance and durability, making it an ideal choice for demanding industrial applications.

1. Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a lab coat or apron when working with graphite plates. This will help protect you from any potential hazards. 2. Ensure that the work area is well-ventilated. Graphite dust or particles can be harmful if inhaled, so it is important to have proper ventilation to minimize exposure. 3. Handle graphite plates with care to avoid any damage or breakage. Graphite is a brittle material and can easily chip or crack if mishandled. Use both hands when lifting or moving graphite plates to distribute the weight evenly. 4. Avoid excessive pressure or force when working with graphite plates. Applying too much pressure can cause the graphite to break or splinter. Use gentle and controlled movements when working with the plates. 5. Keep graphite plates away from open flames or high heat sources. Graphite is a good conductor of heat and can become extremely hot when exposed to high temperatures. This can cause burns or fire hazards. 6. Clean up any graphite dust or debris promptly. Use a damp cloth or vacuum with a HEPA filter to remove any loose particles. Avoid using compressed air or dry sweeping methods, as this can disperse the dust into the air. 7. Store graphite plates in a dry and cool area. Moisture can cause graphite to deteriorate or become less effective. Keep the plates in a sealed container or bag to protect them from humidity. 8. If you are unsure about any aspect of working with graphite plates, consult the manufacturer's instructions or seek guidance from a knowledgeable supervisor or expert.

Please note, not all safety data for this product is available on our website, for a complete list of P en H sentences and other safety instructions please request the MSDS at our customer service

Graphite plate is a versatile and high-performance material used in various industries for its exceptional thermal conductivity, electrical conductivity, and chemical resistance properties. It is commonly used in applications such as heat exchangers, electrodes, and lubricants. With its unique combination of properties, graphite plate offers excellent performance and durability, making it an ideal choice for demanding industrial applications.

1. Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a lab coat or apron when working with graphite plates. This will help protect you from any potential hazards. 2. Ensure that the work area is well-ventilated. Graphite dust or particles can be harmful if inhaled, so it is important to have proper ventilation to minimize exposure. 3. Handle graphite plates with care to avoid any damage or breakage. Graphite is a brittle material and can easily chip or crack if mishandled. Use both hands when lifting or moving graphite plates to distribute the weight evenly. 4. Avoid excessive pressure or force when working with graphite plates. Applying too much pressure can cause the graphite to break or splinter. Use gentle and controlled movements when working with the plates. 5. Keep graphite plates away from open flames or high heat sources. Graphite is a good conductor of heat and can become extremely hot when exposed to high temperatures. This can cause burns or fire hazards. 6. Clean up any graphite dust or debris promptly. Use a damp cloth or vacuum with a HEPA filter to remove any loose particles. Avoid using compressed air or dry sweeping methods, as this can disperse the dust into the air. 7. Store graphite plates in a dry and cool area. Moisture can cause graphite to deteriorate or become less effective. Keep the plates in a sealed container or bag to protect them from humidity. 8. If you are unsure about any aspect of working with graphite plates, consult the manufacturer's instructions or seek guidance from a knowledgeable supervisor or expert.

Please note, not all safety data for this product is available on our website, for a complete list of P en H sentences and other safety instructions please request the MSDS at our customer service

You May Also Like

1-(4-Bromophenyl)pentan-1-one, 95.0%, 500g

1-(4-Bromophenyl)pentan-1-one, 95.0%, 500g

SKU F337001-500G

€ 143,00

End user declaration required

3-Methoxybenzonitrile>95.0%(GC)5g

3-Methoxybenzonitrile>95.0%(GC)5g

Only for registered companies

SKU M1291-5G

€ 23,10

5-Aminoisoindoline-2-carbaldehyde, 95%, 1g

5-Aminoisoindoline-2-carbaldehyde, 95%, 1g

SKU F744201-1G

€ 1 384,90

8-Bromo-3-chloroisoquinoline, 95+%, 250mg

8-Bromo-3-chloroisoquinoline, 95+%, 250mg

SKU F624597-250MG

€ 112,20

Display prices in:EUR

![Spiro[fluorene-9,9'-xanthene]-3',6'-diol>98.0%(GC)5g Spiro[fluorene-9,9'-xanthene]-3',6'-diol>98.0%(GC)5g](https://d2j6dbq0eux0bg.cloudfront.net/images/88473019/4044865681.jpg)

![5,7-DICHLORO-2-METHYL-2H-PYRAZOLO[4,3-D]PYRIMIDINE, 95.0%, 10g 5,7-DICHLORO-2-METHYL-2H-PYRAZOLO[4,3-D]PYRIMIDINE, 95.0%, 10g](https://d2j6dbq0eux0bg.cloudfront.net/images/88473019/4863994448.png)

![2-chloro-N-[4-(4-chlorophenoxy)phenyl]acetamide, 1g 2-chloro-N-[4-(4-chlorophenoxy)phenyl]acetamide, 1g](https://d2j6dbq0eux0bg.cloudfront.net/images/88473019/4860176224.png)