Verzending 24–48 u • Levering in de hele EU • Veilige chemieverpakking

Vanadium chips 99.9% 25 g

SKU MV003

€ 197,10

In stock

1

Save this product for later

Vanadium chips 99.9% 25 g

Product Details

Cation: V

Packaging: 25 g

EAN: 8721028259158

Brand: Laboratoriumdiscounter

Vanadium chips are the latest innovation in semiconductor technology, offering unparalleled performance and efficiency. These cutting-edge chips utilize vanadium, a rare and highly conductive metal, to deliver lightning-fast processing speeds and reduced power consumption. With their unique composition, vanadium chips are poised to revolutionize industries such as artificial intelligence, data centers, and high-performance computing. Stay ahead of the curve and unlock the full potential of your devices with vanadium chips.

1. Always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and a lab coat when working with vanadium chips. This will help protect you from potential hazards. 2. Ensure that you are working in a well-ventilated area or under a fume hood to minimize exposure to any potential fumes or dust generated during the handling or manipulation of vanadium chips. 3. Vanadium chips should be handled with care to avoid any sharp edges or splinters. Use appropriate tools, such as tweezers or forceps, to handle the chips and avoid direct contact with your skin. 4. Avoid ingestion or inhalation of vanadium chips. Do not eat, drink, or smoke in the work area to prevent accidental ingestion. Additionally, avoid breathing in any dust or particles that may be generated during the handling process. 5. Store vanadium chips in a secure and labeled container when not in use. This will prevent accidental spills or exposure to others. 6. In case of accidental exposure or injury, seek immediate medical attention. Rinse any affected area with plenty of water and remove contaminated clothing if necessary. 7. Follow proper disposal procedures for vanadium chips and any associated waste. Consult local regulations or guidelines for the appropriate disposal methods. 8. Familiarize yourself with the Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) for vanadium chips. This document provides important information on the potential hazards, handling, storage, and emergency procedures related to vanadium chips. 9. Regularly clean your work area and equipment to minimize the risk of contamination or accidental exposure. 10. Finally, always follow any additional safety guidelines or protocols provided by your employer or institution when working with vanadium chips.

Please note, not all safety data for this product is available on our website, for a complete list of P en H sentences and other safety instructions please request the MSDS at our customer service

You May Also Like

End user declaration required

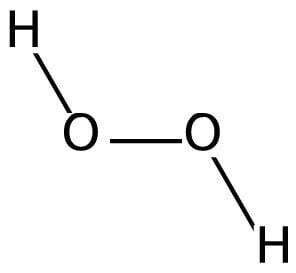

Hydrogen peroxide 35 % foodgrade 1 Liter

Hydrogen peroxide 35 % foodgrade 1 Liter

Only for registered companies

SKU 93683.11

€ 21,40

Display prices in:EUR