Verzending 24–48 u • Levering in de hele EU • Veilige chemieverpakking

Tungsten powder (Mo 5 ppm) 99.99+% 100 g

SKU 902082

€ 427,68

In stock

1

Save this product for later

Tungsten powder (Mo 5 ppm) 99.99+%

100 g

Product Details

CAS number: 7440-33-7

Cation: W

Packaging: 100 g

EAN: 8721028258588

Brand: Laboratoriumdiscounter

Tungsten powder (Mo 5 ppm) is a highly sought-after material known for its exceptional strength and durability. With a low molybdenum content of just 5 ppm, this tungsten powder offers superior purity and performance. Ideal for various industrial applications, it is widely used in the production of high-quality alloys, cutting tools, and electrical contacts. Its unique properties make it an essential component in industries such as aerospace, automotive, and electronics. Choose tungsten powder (Mo 5 ppm) for unmatched reliability and efficiency in your manufacturing processes.

When working with Tungsten powder containing 5 ppm of Molybdenum (Mo), it is important to follow safety precautions to minimize the risk of exposure and potential hazards. Here are some short safety instructions to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, safety goggles, and a lab coat or protective clothing, to protect your skin, eyes, and body from direct contact with the powder. 2. Ventilation: Work in a well-ventilated area or use local exhaust ventilation to prevent the accumulation of airborne particles. Avoid inhaling the powder or creating dust. 3. Handling: Handle the Tungsten powder with care to prevent spills or dispersion. Use appropriate tools and containers to minimize the risk of accidental release. 4. Storage: Store the powder in a tightly sealed container in a cool, dry area away from incompatible materials. Follow proper labeling and storage guidelines to prevent cross-contamination. 5. Hygiene: Practice good personal hygiene by washing hands thoroughly with soap and water after handling the powder. Avoid touching your face, mouth, or eyes while working with the material. 6. Waste Disposal: Dispose of any waste or unused powder according to local regulations and guidelines. Do not dispose of it in regular trash or down the drain. 7. Emergency Procedures: Familiarize yourself with emergency procedures, including spill cleanup and first aid measures. Have appropriate safety equipment and materials readily available in case of accidents or exposure. 8. Training and Awareness: Ensure that all personnel working with Tungsten powder are properly trained on its safe handling, storage, and disposal. Regularly review safety protocols and keep updated on any new information or guidelines. Remember, these instructions are a general guideline, and it is essential to consult the specific safety data sheet (SDS) provided by the manufacturer for detailed information on handling and safety precautions for the specific Tungsten powder you are working with.

Please note, not all safety data for this product is available on our website, for a complete list of P en H sentences and other safety instructions please request the MSDS at our customer service

You May Also Like

End user declaration required

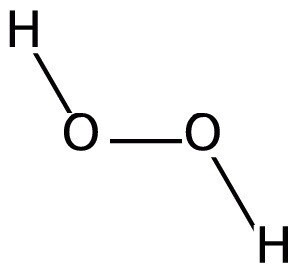

Hydrogen Peroxide, Ph.Eur., Ultra Pure 500 Milliliter 35% Glas

Hydrogen Peroxide, Ph.Eur., Ultra Pure 500 Milliliter 35% Glas

Only for registered companies

SKU 572145.4.2

€ 33,10

End user declaration required

Sodium chlorite 80% 20 Kilogram

Sodium chlorite 80% 20 Kilogram

Only for registered companies

SKU 9374.2.6

€ 524,37

Sodium hexametaphosphate 99+% 25 Kilogram

Sodium hexametaphosphate 99+% 25 Kilogram

SKU NHMF7561.3

€ 180,50

End user declaration required

Hydrogen peroxide 35 % foodgrade 5 Liter

Hydrogen peroxide 35 % foodgrade 5 Liter

Only for registered companies

SKU 91683.51

€ 55,65

Display prices in:EUR