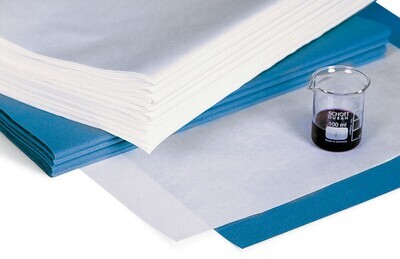

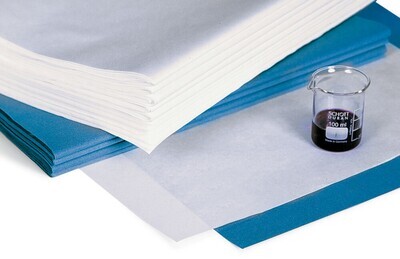

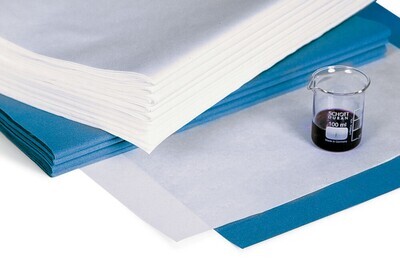

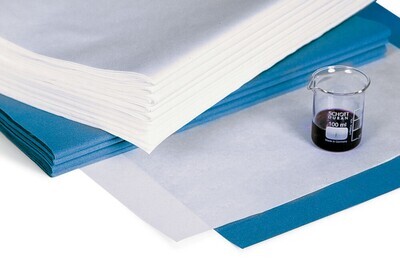

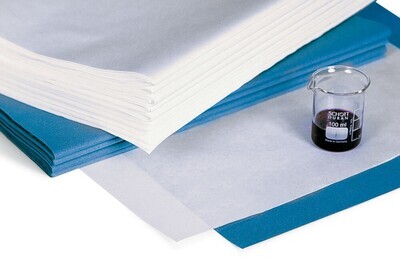

Filter paper

Filter paper is an essential part of many industrial processes and laboratory experiments. It is used to separate solids from liquids through filtration. This process is of great importance in various sectors, such as the chemical industry, food industry, pharmaceutical industry and environmental technology. Filter paper is made of cellulose fibers compressed into a thin, porous and absorbent structure. This structure allows liquids to flow easily through the paper, while solid particles are retained. The paper can have different pore sizes depending on the desired filtration rate and the size of the particles to be removed. There are several types of filter paper available, each with their own unique properties and applications. For example, there is quantitative filter paper, which is used for weighing solids after filtration. This paper has a high retention capacity and is resistant to strong chemicals. In addition, there is high-quality filter paper, which is used for separating solids from liquids in laboratory experiments. This paper has a finer pore size and is suitable for filtering small particles. In addition to these standard filter papers, specialized variants are also available. For example, there is asbestos-free filter paper, which offers a safe alternative to traditional asbestos-containing filter paper. This paper is suitable for filtration of aggressive chemicals and high temperatures. In addition, there is fiberglass filter paper, which has high chemical resistance and temperature resistance. This paper is often used in the petrochemical industry and in air and water purification. Using filter paper offers many advantages. First, it ensures efficient separation of solids and liquids, allowing pure liquids to be obtained. In addition, filter paper is easy to use and can be quickly replaced when saturated. In addition, filter paper is relatively cheap and available in different sizes and shapes, making it suitable for various applications. When choosing the right filter paper, it is important to consider the desired filtration rate, the size of the particles to be removed and the chemical resistance of the paper. In addition, it is important to check whether the filter paper complies with applicable standards and guidelines, such as ISO 9001 and FDA approval. In short, filter paper is an indispensable material for filtration processes in various industries. It provides an efficient and reliable way to separate solids from liquids. With the right choice of filter paper, optimal filtration can be achieved, resulting in pure and high-quality liquids.

Refine by

Powered by Lightspeed

Display prices in:EUR